Using CNC CAM software for CNC machining is essential for precision, efficiency, and productivity. CAM software converts your CAD designs into accurate toolpaths, ensuring that machines cut materials exactly as intended. It minimizes errors, reduces material waste, and speeds up production by automating complex calculations and movements. Advanced CAM programs also allow simulation of machining processes, helping detect potential issues before actual production. Whether working with 2D, 3D, or multi-axis operations, CAM software streamlines workflow, optimizes cutting strategies, and improves consistency. For both professionals and hobbyists, using CNC CAM software is the key to achieving high-quality, reliable, and efficient machining results.

What are these 10 Software?

1. CATIA

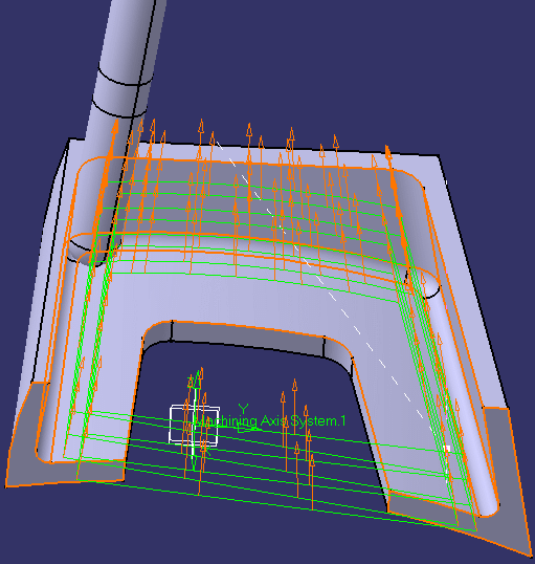

CATIA is considered one of the best CAM software for CNC machining due to its powerful combination of design, engineering, and manufacturing capabilities. It supports complex multi-axis machining, precise toolpath generation, and advanced simulation, ensuring high accuracy and efficiency.

CATIA’s seamless integration with CAD models allows users to directly create CNC-ready toolpaths without data loss, saving time and reducing errors. Its robust features for aerospace, automotive, and industrial applications make it ideal for handling large assemblies and intricate components. With reliable post-processing and extensive machine compatibility, CATIA empowers engineers to optimize production, improve quality, and achieve consistent, professional-grade machining results.

2. MasterCAM

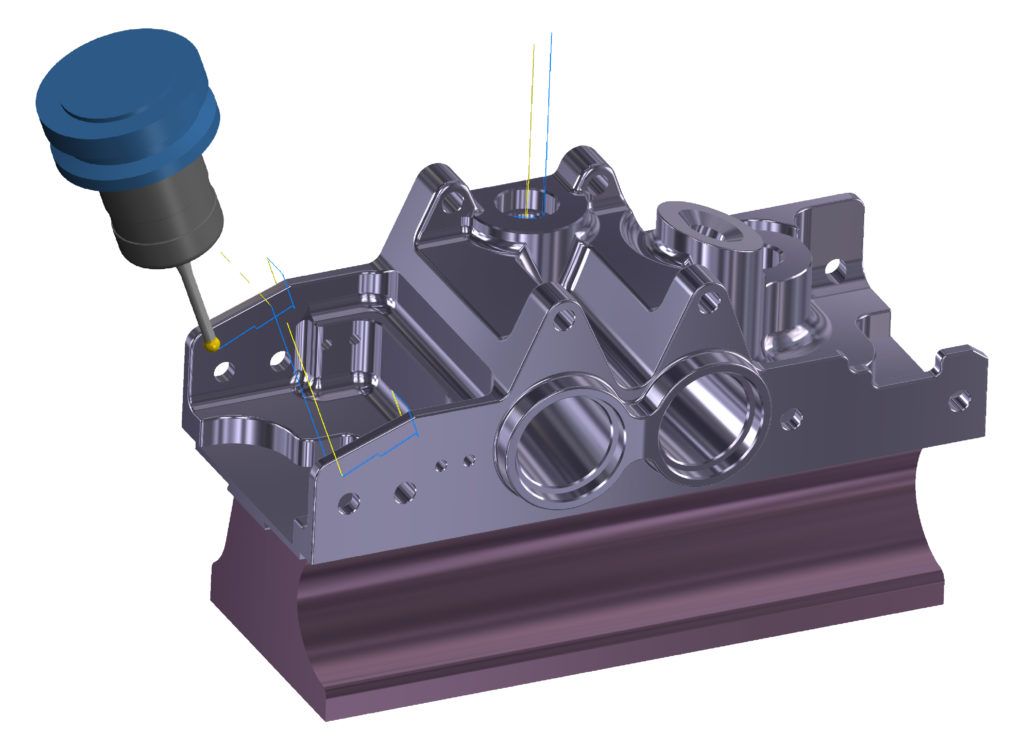

Mastercam is widely regarded as one of the best CAM software for CNC machining due to its versatility, reliability, and user-friendly interface. It supports 2D, 3D, and multi-axis machining, making it suitable for a wide range of industries, from manufacturing to aerospace.

Mastercam provides precise toolpath generation, reducing errors and material waste while optimizing machining efficiency. Its powerful simulation features allow users to visualize operations before actual production, preventing costly mistakes. With extensive post-processing options and strong community support, Mastercam enables engineers and machinists to streamline workflows, enhance productivity, and achieve consistently accurate, high-quality CNC machining results.

3. Fusion 360

Fusion 360 is considered one of the best CAM software for CNC machining because it combines cloud-based CAD, CAM, and CAE in a single platform. It allows seamless design-to-manufacturing workflows, enabling users to create, simulate, and generate CNC toolpaths efficiently.

Fusion 360 supports 2.5D, 3D, and multi-axis machining with adaptive strategies that reduce cycle time and material waste. Its intuitive interface and collaborative cloud features make it ideal for both beginners and professionals. With integrated simulation, real-time feedback, and extensive machine compatibility, Fusion 360 streamlines CNC machining processes, ensuring precision, productivity, and high-quality results for any manufacturing project.

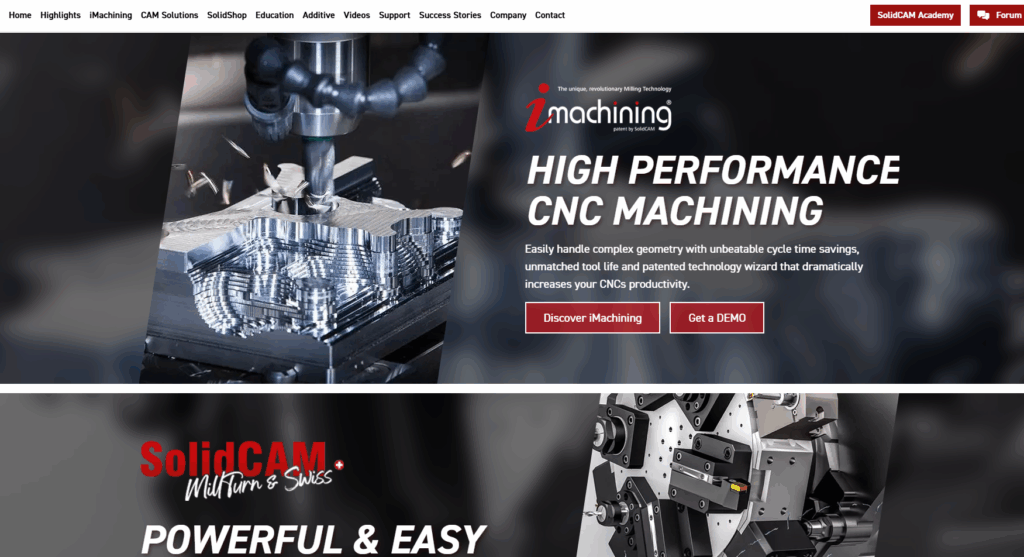

4. SolidCAM

SolidCAM is considered one of the best CAM software for CNC machining due to its seamless integration with SolidWorks, allowing engineers to create toolpaths directly from 3D models without data loss. Its patented iMachining technology optimizes cutting strategies, reduces cycle times, and extends tool life, making machining highly efficient and cost-effective.

SolidCAM supports 2.5D, 3D, and multi-axis operations, providing versatility for a wide range of industries, from automotive to aerospace. With realistic simulation, automatic collision detection, and precise post-processing, SolidCAM ensures accuracy, reliability, and high-quality results, empowering professionals to streamline CNC machining workflows and maximize productivity.

5. Esprit

Esprit is one of the best CAM software for CNC machining because it combines power, versatility, and ease of use in a single platform. It supports milling, turning, wire EDM, and multitasking operations, making it suitable for a wide range of industries and applications.

Esprit’s intelligent toolpath strategies optimize cutting efficiency, reduce cycle times, and minimize material waste. Its advanced simulation and verification tools allow users to detect collisions and errors before production, ensuring precision and safety. With extensive machine compatibility and customizable post-processors, Esprit enables engineers and machinists to achieve high-quality, reliable, and efficient CNC machining results consistently.

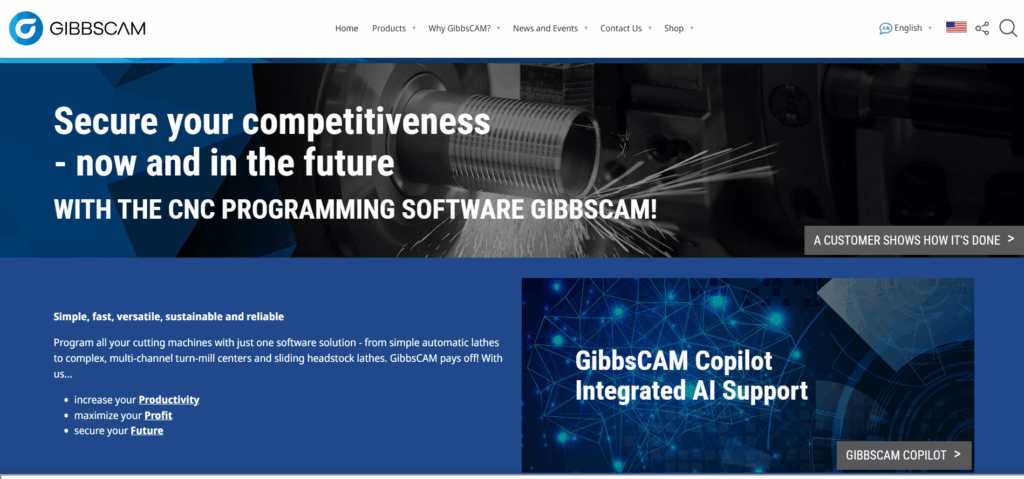

6. GibbsCAM

GibbsCAM is widely recognized as one of the best CAM software for CNC machining due to its intuitive interface, powerful capabilities, and flexibility. It supports milling, turning, mill-turn, and multi-axis operations, making it suitable for a broad range of industries.

GibbsCAM’s feature-based programming simplifies complex toolpath creation, reducing programming time and minimizing errors. Its advanced simulation tools allow users to visualize machining processes, detect collisions, and optimize operations before production. With reliable post-processing, extensive machine compatibility, and strong customer support, GibbsCAM helps engineers and machinists achieve precise, efficient, and high-quality CNC machining results while streamlining workflow and boosting productivity.

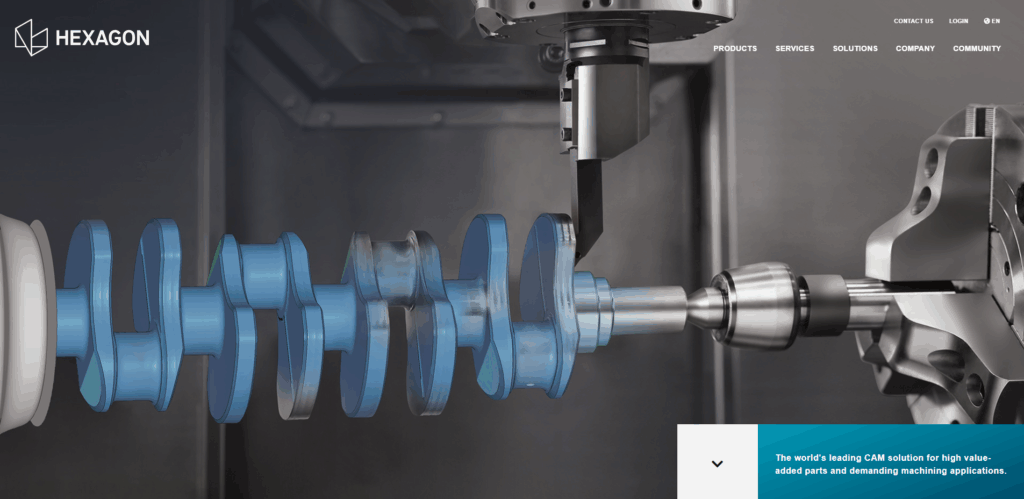

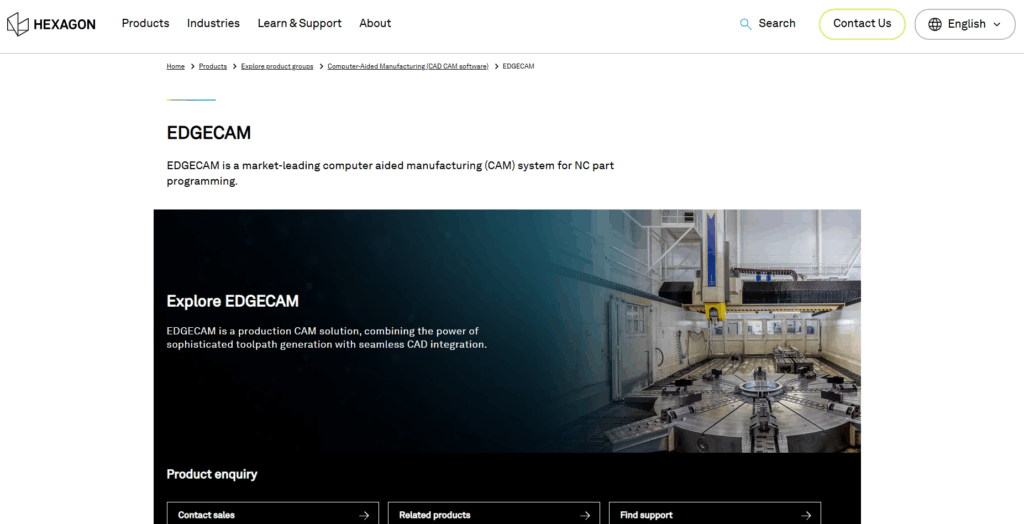

7. EdgeCAM

Edgecam is considered one of the best CAM software for CNC machining because of its robust functionality, ease of use, and versatility across industries. It supports milling, turning, and mill-turn operations, including complex multi-axis machining.

Edgecam’s advanced toolpath strategies optimize cutting efficiency, reduce cycle times, and extend tool life, saving both time and material. Its powerful simulation and verification tools allow users to visualize machining processes, detect collisions, and ensure precision before production. With seamless integration, customizable post-processors, and reliable machine compatibility, Edgecam enables engineers and machinists to achieve consistent, high-quality CNC machining results while improving workflow and overall productivity.

8. BobCAD-CAM

BobCAD-CAM is one of the best CAM software for CNC machining because it offers a perfect balance of power, affordability, and flexibility. It supports milling, turning, routing, and multi-axis machining, making it suitable for both beginners and professionals. The software provides intuitive toolpath creation, simulation, and optimization tools that improve accuracy and reduce machining time.

BobCAD-CAM’s modular design allows users to customize features based on their needs, ensuring cost-effective performance. With strong post-processing options and compatibility with a wide range of CNC machines, BobCAD-CAM helps manufacturers streamline production, minimize errors, and achieve precise, high-quality results efficiently and consistently.

9. CAMWorks

CAMWorks is considered one of the best CAM software for CNC machining because it integrates seamlessly with SolidWorks and Solid Edge, enabling feature-based programming directly from 3D models. Its automated toolpath generation and knowledge-based machining reduce programming time, minimize errors, and increase efficiency.

CAMWorks supports 2.5D, 3D, turning, and multi-axis operations, making it versatile for various industries. Advanced simulation and verification tools allow users to visualize machining processes and prevent collisions before production. With customizable post-processors and reliable machine compatibility, CAMWorks empowers engineers and machinists to achieve precise, high-quality CNC machining results while optimizing workflow and productivity.

10. TopSolid

TopSolid is considered one of the best CAM software for CNC machining because it offers a fully integrated CAD/CAM solution, allowing seamless design-to-manufacturing workflows. It supports milling, turning, wire EDM, and multi-axis operations, making it highly versatile for complex projects.

TopSolid’s intelligent toolpath strategies optimize cutting efficiency, reduce cycle times, and extend tool life, ensuring cost-effective production. Its advanced simulation and verification tools allow users to detect collisions and errors before machining, guaranteeing precision and safety. With customizable post-processors, strong machine compatibility, and a user-friendly interface, TopSolid empowers engineers and machinists to achieve consistent, high-quality CNC machining results efficiently.