People use free CNC machining CAM software because it gives them the ability to create precise toolpaths and manufacturing programs without the high cost of commercial software. Many small businesses, students, and hobby machinists want to learn CNC programming or run simple projects, but professional CAM tools can be too expensive for their needs. Free solutions provide the same core features—such as generating G-code, simulating tool motion, and setting cutting parameters—without financial pressure.

Free CAM software also helps users experiment and learn. It allows beginners to understand machining concepts like feed rates, cutting depths, and tool strategies before working in an industrial environment. Open-source programs, such as FreeCAD or PyCAM, even let users explore and modify the code, giving them deeper control over how their machining data is generated.

Another reason people choose free CAM tools is flexibility and community support. Many free applications have strong online communities that share tutorials, post-processors, and troubleshooting advice. This collective knowledge helps users improve their skills faster.

In short, people use free CNC machining CAM software because it offers freedom to learn, create, and innovate—making advanced manufacturing accessible to anyone, regardless of budget or professional background.

What are these Best Free CAM Software?

1. Fusion 360

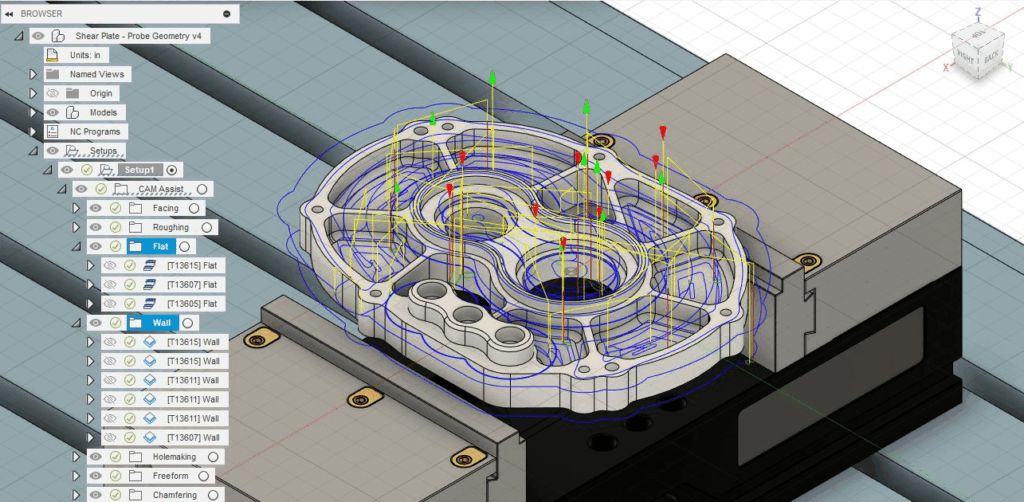

People use the free version of Fusion 360 for CNC machining because it combines powerful design and manufacturing tools in a single, easy-to-use platform. The personal-use license gives hobbyists, students, and small workshops access to professional-grade CAD and CAM features without paying for an expensive subscription. This makes it ideal for anyone learning CNC machining or running small projects where commercial software would be unaffordable.

Fusion 360’s free version still includes essential CAM capabilities such as 2D and 3D toolpath creation, G-code generation, and simulation. Users can design parts, test tool movements, and verify machining results before cutting material, reducing mistakes and wasted resources. The software also supports a wide range of CNC machines, making it flexible for different workshop setups.

Another reason for its popularity is its strong community and cloud integration. Tutorials, forums, and shared projects make it easy to learn and solve problems. The cloud-based environment allows users to save, update, and collaborate on designs from anywhere.

Overall, people use the free Fusion 360 CAM software because it offers a professional-level experience at no cost, empowering learners and makers to produce high-quality CNC parts efficiently and confidently without large financial investment.

2. FreeCAD

People use the free CNC machining CAM software FreeCAD because it provides a complete, open-source solution for designing and manufacturing parts without any licensing cost. It’s especially popular among students, hobby machinists, and small workshops who need reliable CAM features but can’t afford expensive commercial software. FreeCAD’s Path Workbench allows users to generate toolpaths, simulate machining operations, and export G-code for CNC machines, all within the same environment used for 3D design.

Another reason people prefer FreeCAD is its flexibility and transparency. Since it is open source, users can customize or extend the software through Python scripts and community add-ons. This freedom makes it adaptable for different CNC machines, workflows, and personal preferences. Unlike closed commercial systems, FreeCAD encourages users to understand how toolpaths are created and optimized, which helps in developing real machining knowledge.

FreeCAD also benefits from an active global community that constantly improves the program, shares tutorials, and offers free technical help. This support network makes it easier for newcomers to learn CNC machining and design. In summary, people use FreeCAD for CNC work because it’s powerful, free, customizable, and built by a community that values accessibility and learning for everyone.

3. PyCAM

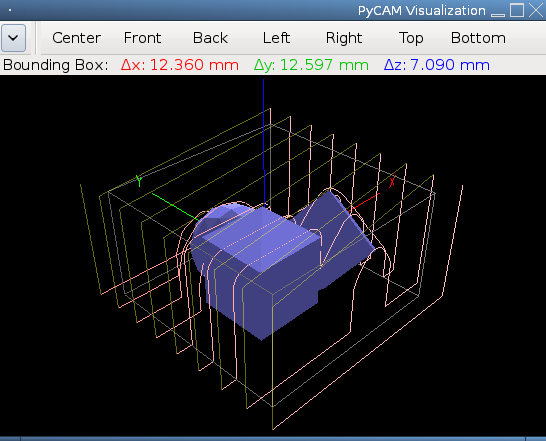

People use the free CNC machining CAM software PyCAM because it offers a simple, open-source way to create toolpaths and G-code for milling machines without paying for commercial programs. It’s ideal for hobbyists, educators, and small workshops who need reliable 3-axis machining functions but don’t require advanced industrial features. With PyCAM, users can import 3D models in formats like STL or DXF and quickly generate cutting paths for roughing, finishing, and contouring operations.

One of the main reasons for PyCAM’s popularity is its accessibility and openness. Since it’s open-source, anyone can study, modify, or improve the software to suit their specific machining needs. This makes it a valuable learning tool for people who want to understand how toolpath generation and G-code creation work at a deeper level.

PyCAM also runs on multiple operating systems, including Linux and Windows, making it flexible for different users. Its lightweight design allows it to run on modest hardware, which is useful for schools or small shops. Additionally, the PyCAM community shares scripts, updates, and tutorials, helping newcomers get started easily.

In short, people use PyCAM because it’s free, open, and effective—offering essential CAM functionality while promoting learning and independence in CNC machining.

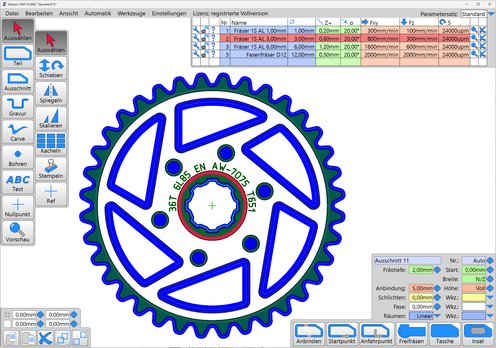

4. Estlcam

People use the free CNC machining CAM software Estlcam because it combines simplicity, reliability, and powerful features that make it accessible to beginners and small workshop owners. Although Estlcam offers a paid license, its free version provides more than enough tools for learning and running basic machining projects. It allows users to easily create toolpaths, generate G-code, and control CNC machines without the complexity found in many professional CAM programs.

One of the main reasons people choose Estlcam is its user-friendly interface. The layout is clean and intuitive, allowing users to move quickly from a 2D drawing or 3D model to a ready-to-run toolpath. This simplicity makes it an excellent choice for hobbyists, educators, and makers who want to understand CNC machining without a steep learning curve.

Another advantage is compatibility. Estlcam supports many CNC controllers and can even act as control software for some machines. It’s efficient, lightweight, and runs smoothly on most Windows systems. The active online community also provides tutorials, troubleshooting help, and shared project files, which encourages learning and experimentation.

Overall, people use Estlcam because it offers professional-quality machining capabilities in an affordable, easy-to-learn package that’s perfect for both beginners and small-scale CNC users.

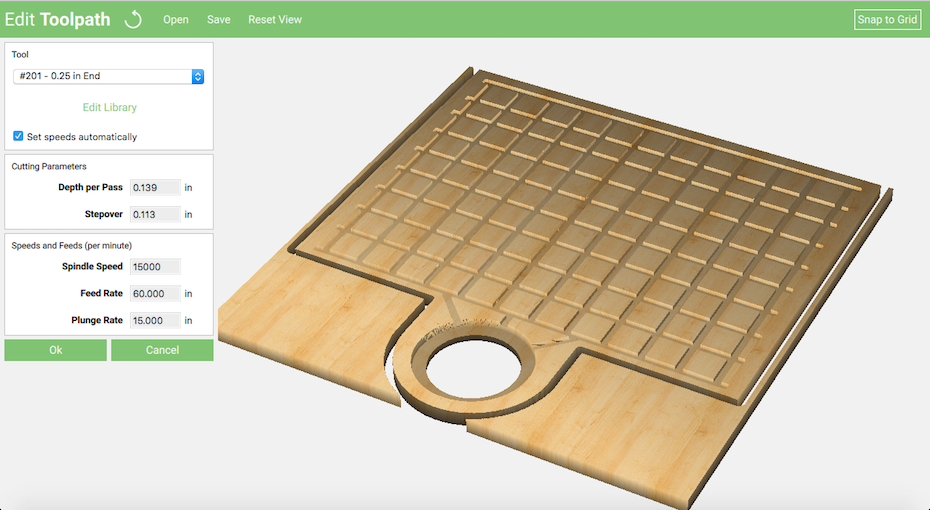

5. Carbide Create

People use the free CNC machining CAM software Carbide Create because it provides an accessible, beginner-friendly way to design and generate toolpaths for CNC milling without the high cost of professional CAM software. Its free version allows hobbyists, educators, and small workshop operators to create 2D and simple 3D designs, generate G-code, and control CNC machines efficiently. This makes it especially appealing to individuals looking to learn CNC machining or complete small-scale projects without financial barriers.

One of the main reasons for its popularity is its intuitive interface. Carbide Create combines CAD and CAM functionality in a single environment, allowing users to design parts, apply toolpaths, and simulate machining operations all in one program. This streamlined workflow reduces complexity, making it easier for beginners to move from concept to finished part quickly.

Carbide Create is also well-optimized for Carbide 3D machines, but it works with other CNC routers as well, providing flexibility for different setups. Its lightweight design ensures smooth performance on standard computers, and the software includes basic but effective 2D/3D machining features, such as pocketing, profiling, and engraving.

In addition, an active community of users shares tutorials, tips, and project files, supporting learning and experimentation. Overall, people use Carbide Create because it delivers a balance of ease-of-use, practical functionality, and accessibility, making CNC machining approachable for everyone.